Product Description

Model NO.: ND-DZX-1

Automatic Production Line: Assembly

Automation: Automation

Rhythm: Flow Production Line

Automation Type: Fully Automatic

Color: Ral9010 or as Per Customer Requirement

Trademark: NIDE

Specification: customized

Transmission Type: Flexible

Certification: CCC

Flexible Production: Intelligent Manufacturing

Production Scope: Product Line

Productitity: High Efficiency

After-Sales Service: Overseas Service Center Available

Transport Package: Container

Origin: China

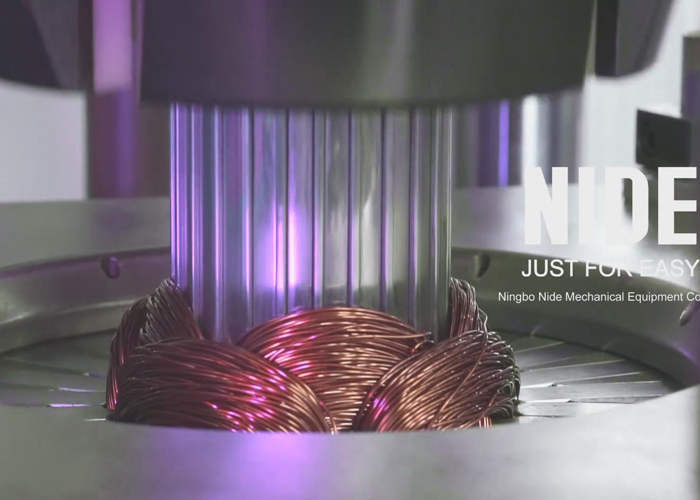

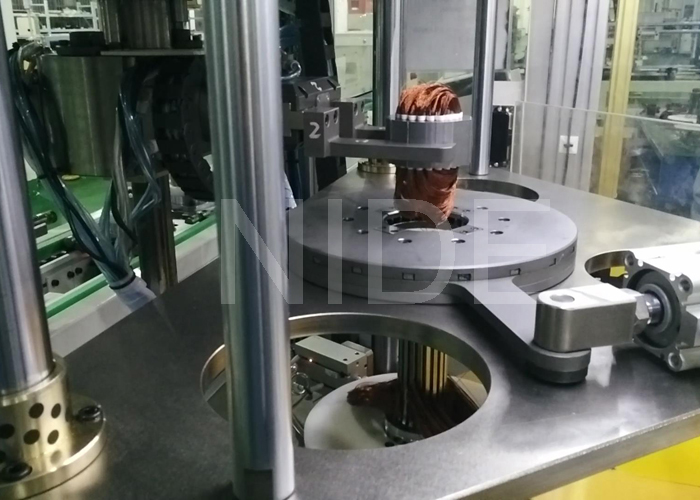

Nide can supply full package of motor stator automatic production machine or line for different motor types, like BLDC, pump motor, car motor, induction motor, 3 phase motor ect. This

Stator Production Line including paper

Inserting Machine,

Coil Winding Machine, coil

Winding Inserting Machine, lacing machine,

Forming Machine and testing machine.

This automatic stator production line including paper inserting machine, coil

Winding Machine, coil winding inserting machine, lacing machine, forming machine and testing machine.

There are serval type of paper inserting machine which can meet various requirement. Theproduction capacity ≤1s/slot (exclude the loading/unloading time). Primary qualification rate ≥99%, after rework, the rate ≥99.9%

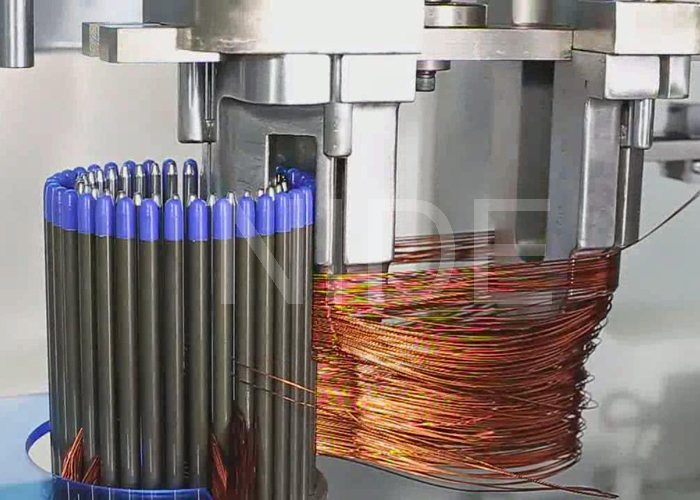

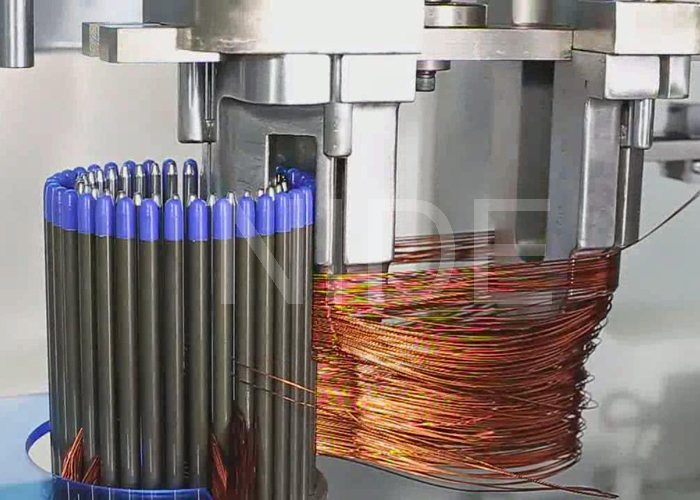

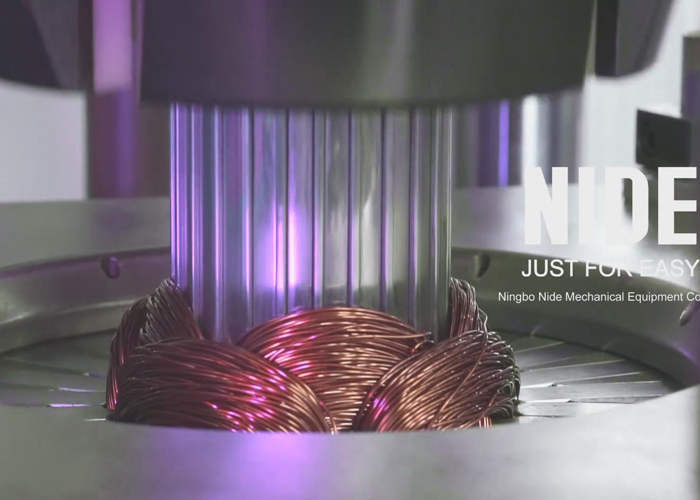

For the coil winding machine, it covers a wide range of stator dimension and wire diameter. meeting the various requirement. The most efficient coil winding machine of this

Stator Production Machine line is equipped with four winding heads and eight operation stations. high slot filling rate, small slot opening stator coil winding. Winding mode, such as auto skip, auto cutting and auto indexing could be completed at a time successively, parameter could be set in human-machine interface. Continuous/discontinues winding way and meets the 2 poles. 4 poles, 6 poles coils winding.

Coil winding inserting machine can insert stator coil and wedge into the stator slot automatically. It reduces the labor and improve the efficiency and accuracy.This machine is suitable for Polyester Film wedge roll material with fixed thickness and fixed width (width and thickness dimension is provided by customer). For the wire, both copper wire and alum wire are OK.

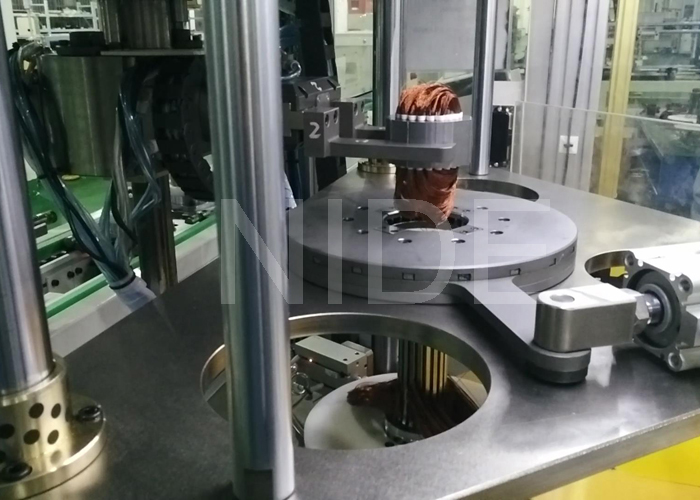

The lacing machine is controlled by PLC. Different lacing mode could be set such as slot lacing, interval lacing, and fancy lacing. Tooling change is fast and convenient. There are single lacing machine, doulble station lacing machine and horizontal lacing machine.

The forming machine is used to do coil forming. Before lacing, the stator coil should do one time forming as it can be better to do lacing. After lacing, the stator coil should do final forming. Production capacity ≤14s/set (exclude loading/unloading time)

After all the above step, the stator production process is finished. Now it needs to do testing to check if it is qualified. The testing machine can test resistance, hi-pot, insulation resistance ect.

Contact us if you need more details on Assembly Line . We are ready to answer your questions on packaging, logistics, certification or any other aspects about

Stator Machine、Stator Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Stator Winding Line > Other Stator Winding Line