Product Description

Model NO.: ND-ZCJ

Driven Type: Electric

Packaging Material: Container

Application: Armature Varnish Coating

Heating Time: Less Than 45

Pitch Time: 0~10 Adjustable

Transport Package: 1 Container

Origin: China

Type: Armature Varnish

Coating Machine Automatic Grade: Automatic

Packaging Type: Metal

Working Station: 124

Tunnel Working Temperature: O~160

Trademark: NIDE

Specification: customized

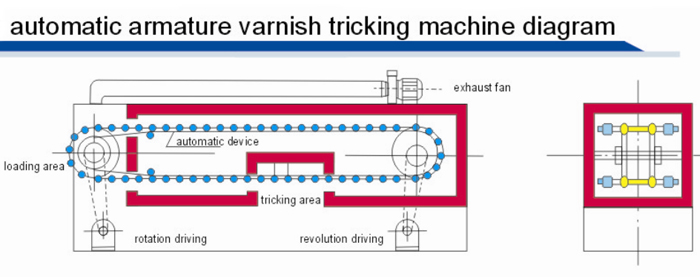

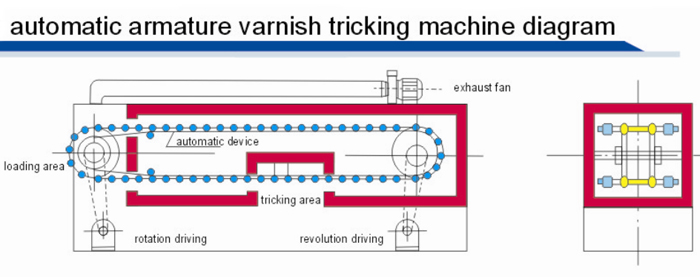

Automatic rotor assembly machine armature varnish trickling machine

Armature trickling machine is mainly used for armature insulation treatment. The whole process, except for loading and unloading armature, is completely automatically. Armature trickling machine can automatically finish the full procedure of pre-heating, air cooling, trickling (rolling), distribute even and post curing, etc. The automatic production guarantees the good and stable quality standard of the armature.In the trickling and post curing area, the armautre all along keeps rotary status, the varnish layer is distributed very even in the armature winding, accordingly ensure the good balance of armature. There is not varnish adhere to shaft and commutator, and therefore save the varnish remove process. Heating tunnel by hot wind circulation, it could ensure the temperature even and reliable.

* Varnish trickling area and colloidizing & curing area, the armatures keep rotation, which ensures even varnish to obtain original balancing.

* Commutator and shaft of the armatures don't have varnish, which remove the extra varnish-shading process to save the labor cost and also ensure the armature precision and good appearance.

* Heating using hot air circulation drying tunnel, the temperature is relatively uniform, safe and reliable.

* Varnish trickling mode: Peristaltic pumps or gear pumps, varnish trickling volume is adjustable;

* Varnish rolling trickling: Pneumatic lift tank;

Control system: Tradition control system (by buttons control) or HMI control system.

Competitive advantages:

The whole process, except for loading and unloading armature, is completely automatically.

Specification:

76

ZDG63-156

50 |

76

ZDG63-156

50 |

76

ZDG63-200

50 |

76

ZDG63-260

50 |

ZDG50-320 | | |

Working position | |

124×2 |

156×2 |

200×2 |

260×2 |

320×2 |

Position pitch |

mm |

76 63 50 |

Heating time |

min |

≤45 |

Tunnel working

temperature |

ºC |

0~160ºC |

Pitch time |

min |

0~10 adjustable |

Power |

kw |

28

25

22 |

36

28

25 |

45

36

28 |

54

45

36 |

40 |

Machine dimension |

m |

4.9×1.6×2.1

4.1×1.6×2.1

3.2×1.6×2.1 |

6×1.6×2.1

5×1.6×2.1

4×1.6×2.1 |

7.6×1.6×2.1

6.4×1.6×2.1

5.1×1.6×2.1 |

9.8×1.6×2.1

8.2×1.6×2.1

6.6×1.6×2.1 |

3.3×1.6×2.5 |

Weight |

t |

3.5

3

2.5 |

4.2

3.5

3 |

4.8

4.2

3.5 |

5.8

5.1

4.3 |

3.5

|

Contact us if you need more details on

Varnish Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Varnish Trickling Machine、Varnish Coating Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Armature Winding Line > Insulation Treatment Machine

Contact us if you need more details on Varnish Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Varnish Trickling Machine、Varnish Coating Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Varnish Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Varnish Trickling Machine、Varnish Coating Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.