Product Description

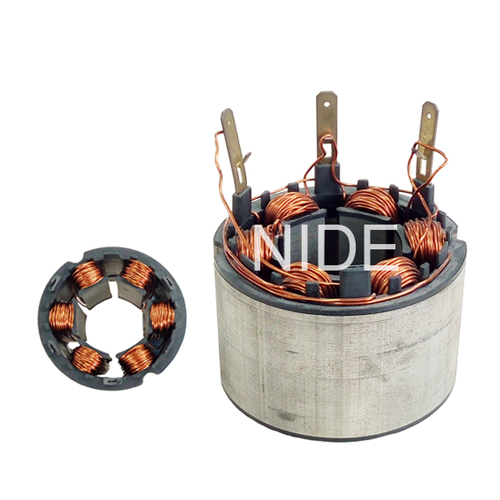

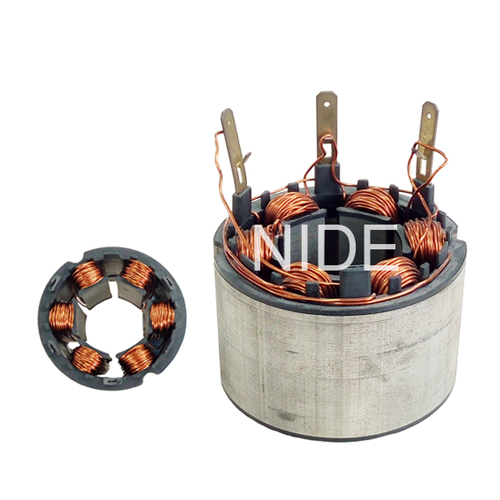

Model NO.: ND-TSM-1 Certification: ISO Condition: New Warranty: 12 Months Wire Diameter: 0.1~0.7mm Slot Number: 6 Poles, 9pole, 12 Poles Air Pressure: 5~7kg/Cm2 Voltage: AC220V, 50/60Hz Dimension: 1600*1100*1400mm Transport Package: Pallet Origin: China Precision: Precision Automatic Grade: Semiautomatic Customized: Customized Stator O.D: 15~65mm Stator Stack Length: 7~100mm Productivity: 3~4min/PC Total Power: 2kw Weight: 450kgs Trademark: NIDE Specification: 1600*1100*1400mm HS Code: 8479811000 Automatic Multi-Pole Stator

Coil Winder Winding Machine Adopt Mitsubishi program controller and GOT, to achieve man-machine interaction, modifying and storing the winding parameter of stator Cam combination which has been calculated precisely assure the precise winding process. Fixed fixture and the structure of using protective sleeve to protect hooking wire assure hanging wire quickly, exactly and safely. Adopt stepping motor to assure stable and precise indexing. Adopt imported aluminum alloy frame. Techniacl data

| Stator O.D | 15~65mm |

| Wire diameter | 0.1~0.7mm |

| Stator stack length | 7~100mmm |

| Turn number | 0~99999 |

| Slot number | 6 poles, 9pole, 12 poles |

| Productivity | 3~4min/pc |

| Air pressure | 5~7Kg/cm2 |

| Total power | 2KW |

| Voltage | AC220V,50/60Hz |

| Weight | 450Kgs |

| Dimension | 1600*1100*1400m |

Maintenance 1. The machine should be installed in the environment with clean air, and suitable humidity. 2. The stepping motor should be keep clean, avoid impaction by hard things. 3. Regularly lubrication. This machine adopts imported lubrication system; fill the oil tank with 40 # oil. It can be judged whether it needs refuel or not through view hole. 4. The critical part of the machine adopts imported high-precision dustproof bearings, normally, it don't need to maintain. If it can't rotate smoothly or choked, need to replace bearings. 5. All of the cylinder are oil-free lubrication types, normally, don't need to add oil to the oil sprayer, while you need to fill the filter with water. 6. The magnetic switch on the cylinder body and the proximity switches on the machine don't need to be adjusted. 7. Don't impact, knock, pierce or press the PLC touching screen and the frame with big force. 8. Don't shake, rotate the PLC touching screen fixing box with big force, also it should be free of great vibration. 9. Keep the touch-screen and the fixing box clean, free of water, oil, dust, or corrosive substances such as acid and alkali, and avoid direct sunlight. 10. Keep machine away from the transformers, high voltage power supply equipment which with strong electromagnetic radiation.

Contact us if you need more details on Winding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

Stator Winding Machine、

Stator Winder. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Stator Winding Line > Coil Winding Machine

Contact us if you need more details on Winding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stator Winding Machine、Stator Winder. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Winding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stator Winding Machine、Stator Winder. If these products fail to match your need, please contact us and we would like to provide relevant information.